Aidtherm 956

Aidtherm 956

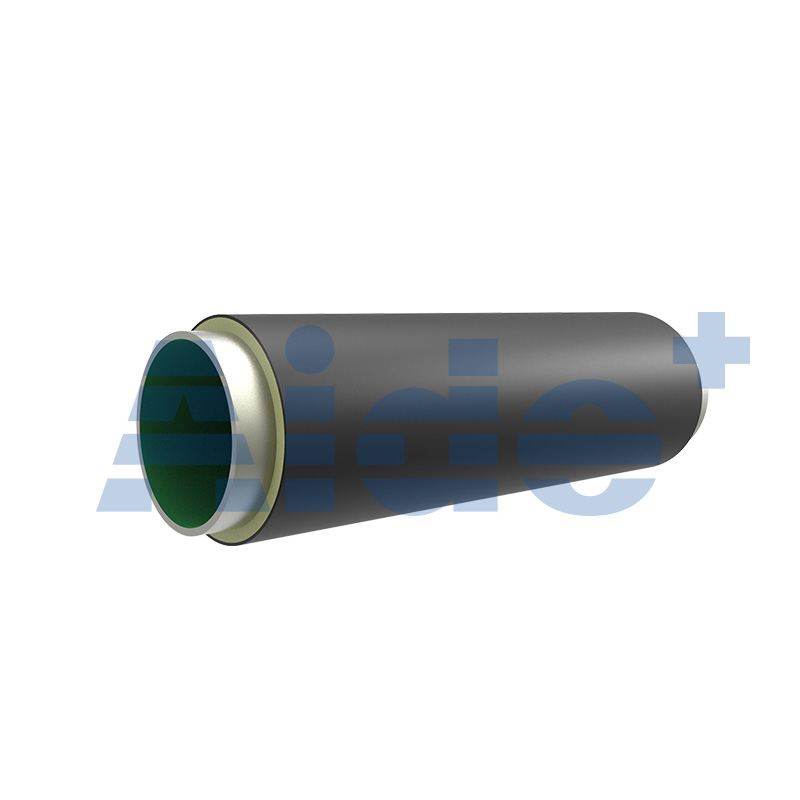

Aidtherm 956 is a mixture of polyether polyol, water, stabilizers, accelerators, etc., mixed with polymeric MDI at a ratio of 1.5:1, and then poured into the cavity between the steel pipe and the outer protective pipe to form rigid polyurethane Foam. The system uses water as a chemical blowing agent to react with excess polymerized MDI to generate carbon dioxide, and at the same time generate a temperature-resistant foam in which polyurethane and polyisocyanurate coexist. It is an environmentally friendly system that is harmless to the environment. The system is developed for long-distance, large-diameter, direct-buried thermal insulation pipelines with a temperature resistance of no more than 140 degrees.

● The system contains all the additives and can be used directly

● The foam system has good fluidity and uniform density distribution

● The resulting foam has high compressive strength, good dimensional stability and low water absorption

● When the outer tube and steel pipe are preheated to 30-40℃, the foam has a strong bonding force with the outer tube and steel pipe

● Heat resistance performance (estimated value) 142℃ or less continuous operation for 30 years

● Environmentally friendly system that does not damage the ozone layer